The Ultimate Guide: When to replace your running shoes

You will have no doubt heard the advice when it comes to replacing your running shoes: replace them every 500 miles or so. In fact, this rough benchmark has even caused Strava to have an ‘alert’ set up for when your shoes reach at least 400km. So, why have my INOV8 X-Talon 255s lasted over 1000 miles of brutal running?

We are often asked when you should replace your running shoes, and whether there is merit in this life expectancy for your shoes. Here we unpack the reason the 500-mile number exists and what you should really be looking for when it comes time to replace your beloved kicks.

Co-founder Damian Hall and his beloved Inov-8 Trailfly 270s. Credit: inov8.com/ Rob MacFarlane

The origins of the 500-mile rule

Where exactly the 500-mile rule came from is largely lost to the mists of time. There is a 1996 study which suggests that running injuries could be reduced by replacing shoes every 500 to 700km (310 miles to 425 miles), but that study is now almost 30 years old, and hardly relevant to today’s technological advances in footwear. There have been other studies showing some correlation, with some suggesting a rotation of shoes to be the best way to avoid injury as opposed to a defined number of miles.

What is more likely is the 500-mile figure was found during testing by a larger footwear company, possibly 30-plus years ago. Speaking to those in the industry, Nike and Adidas are usually the brands to test shoes under various conditions, but they often don’t share these figures publicly. Over the years, as employees of these companies move around the industry the “general rule” gets spread. It becomes a ballpark figure for companies to fall back on, both so you purchase more shoes, but also so they have something to point at when you get angry your shoes have worn down.

Putting 500-miles under the microscope

Testing shoes is an incredibly fickle business. How do you simulate the real world in a lab? Lab tests are notoriously flawed because they rely on standardisation – standard subjects, standard conditions. It is also very expensive, so most brands won’t send shoes for lab testing, won’t have a lab in-house, and some might not even send their shoes off for wear testing (which is when athletes test them out).

Keen to learn more?

Check out this video from SATRA – one of the most prestigious footwear testing institutions out there, and used by many brands to test grip, cushioning and durability.

Image from SATRA’s website.

The brands that do test are usually very coy about them, because they provide good marketing opportunities (“Best energy return on the market”), but won’t reveal enough information for you to hold them accountable, or let the competition get too much information.

Where does that leave us, then?

Well, the main reason brands use for replacing your shoes is to avoid injuries. That means they are using the midsole as the indicator for when a shoe is ready to replace – not the outsole or the upper!

If a brand was to run a test on their midsole, they will likely use a Compression Test done in one of two ways:

Repeated compressions

Compressing the foam to a certain level and leaving it there for 24-hours

The second is the most common, as it is the simplest and time-constrained. Meanwhile the first could last days, costing more money.

The limitations

All this sounds simple, right? Or is it? Remember, this is a lab test using a standard methodology and indoors. What happens when we go outside? What other factors come into play?

Weight – This is what we discussed above, but obviously a lighter runner will cause a midsole to squash less

Stride pattern – More strides? That’s more impacts on the midsole

Foot strike – How you land will impact how the midsole wears down

Heat – The higher the temperatures, the faster your midsole will wear down

Terrain – If you are always running on roads, your midsole takes a greater beating, which is why this is a key area of investment for road running brands

Running gait – If you run lighter on your feet you will extend the life of your midsole

Frequency – The more often you run, the less time your midsole has to ‘recover’ and return to its original shape. This is why people who run a lot often rotate a couple of shoes

You can see that in order for a brand to make any meaningful claims on durability, they would have to test dozens (if not hundreds) of different combinations of these variables. All of this costs money.

Furthermore, there is naturally hesitation about publicly displaying mileage estimates for each demographic and situation. If you are an 80kg male in Australia, you will likely be annoyed your shoes are advertised as lasting 100 miles less than a 60kg female in Sweden. Naturally, you’d want your shoes to last the same number of miles, but creating hundreds of different variants of a shoe is not practical.

When should you replace your running shoes?

Now you are aware just how complex and problematic putting a number on a shoe’s life expectancy is, you can see how difficult an absolute number is to rely on. What you need to do is check your shoes yourself.

If you have been running for many years, you will probably have a feel for how long your shoes last for the running you do, and maybe use Strava to help you. For those who still aren’t quite sure, here are a few basic principles.

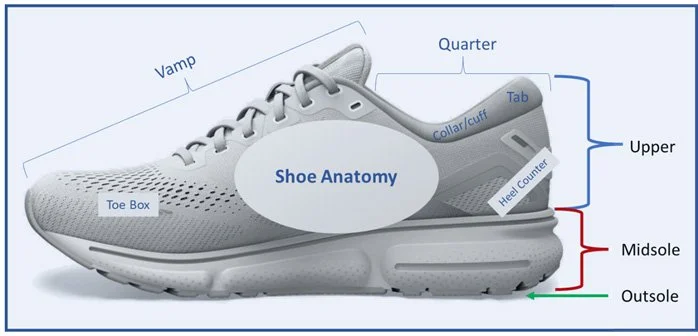

Uppers

The upper of a shoe is the top section, which is where your laces, the tongue and and material surrounding the top of your foot are. Often these break down fairly quickly, depending how soft the material is (or any crease points). The challenge for manufacturers is balancing durability with comfort and breathability. Stiff, tough uppers will last ages, but the shoe will feel less comfortable and maybe a lot tighter; soft uppers are comfy but wear down fast.

Uppers are repairable, though, using a sewing kit or a repair kit like our friends at Pair Ups.

Top tip: Extend the life of your uppers by rinsing your shoes after muddy or sweaty runs. Dirt and sweat eat away at the material meaning they will degrade quicker!

Some very destroyed shoes alongside Jasmin Paris’ repaired Barkley busters!

Midsole

The midsole is the section your foot rests on top of and provides comfort and responsiveness, depending on the materials used.

Give your midsole the Squish Test: If you press the side of a brand new shoe, the midsole should feel firm and bounce back quickly. In a worn midsole, you will see crease marks, and the midsole will feel hard and rebound less when you press it.

Some brands are investing in creating replaceable midsoles, but so far there are few ways to repair a worn midsole.

Top tip: Before you buy a new pair of shoes, run in your own to a running store, try on a new pair of the same (or similar) shoe, and see how big a difference it makes. It might be yours still feel perfectly comfortable! Also, replacing your insoles (the insert your foot actually sits on) might make a huge difference.

The Squish Test

Outsole

The outsole is the bottom section of the shoe, where you find the grip. In road shoes, the outsole sometimes only covers the front or back, with midsole exposed in the middle. In trail shoes, you want consistent grip, so the outsole will cover most of the sole.

Outsoles are easy to monitor wear: The lugs will be smaller, and you might find whole sections worn down to the midsole. Fortunately, outsoles can be repaired. In the UK, we love these shops for repairs:

Kendal Key Cobbler

Cheshire Shoe Repairs

Lancashire Sports Repairs

Old and new – resoled running shoes. Notice how bald the old soles are in places.

Vibram has a network of outsole repair shoes you can find by clicking here. Rest Day provide a similar service in the EU – find them here.

Got some in your country you want others to know about? Let us know!

You know best

Ultimately, you shouldn’t trust a general number as a guiding principle on when to replace your running shoes. Instead, get used to looking at your shoes and spotting wear and tear before it becomes a problem. Look after them and get used to how they feel, because you might get a lot more out of them and save some money!